In the fast-paced world of construction, aluminium formwork has emerged as a groundbreaking innovation that is transforming how buildings are designed and developed. This advanced formwork technology, known for its durability, efficiency, and sustainability, has become the preferred choice for builders and developers across the globe. Offering speed, precision, and cost-effectiveness, aluminium formwork helps deliver consistent quality and long-lasting structures. One of the leading names pioneering this technology is Shriconst Aluform, renowned for delivering world-class formwork solutions that meet the evolving demands of modern construction.

Understanding Aluminium Formwork

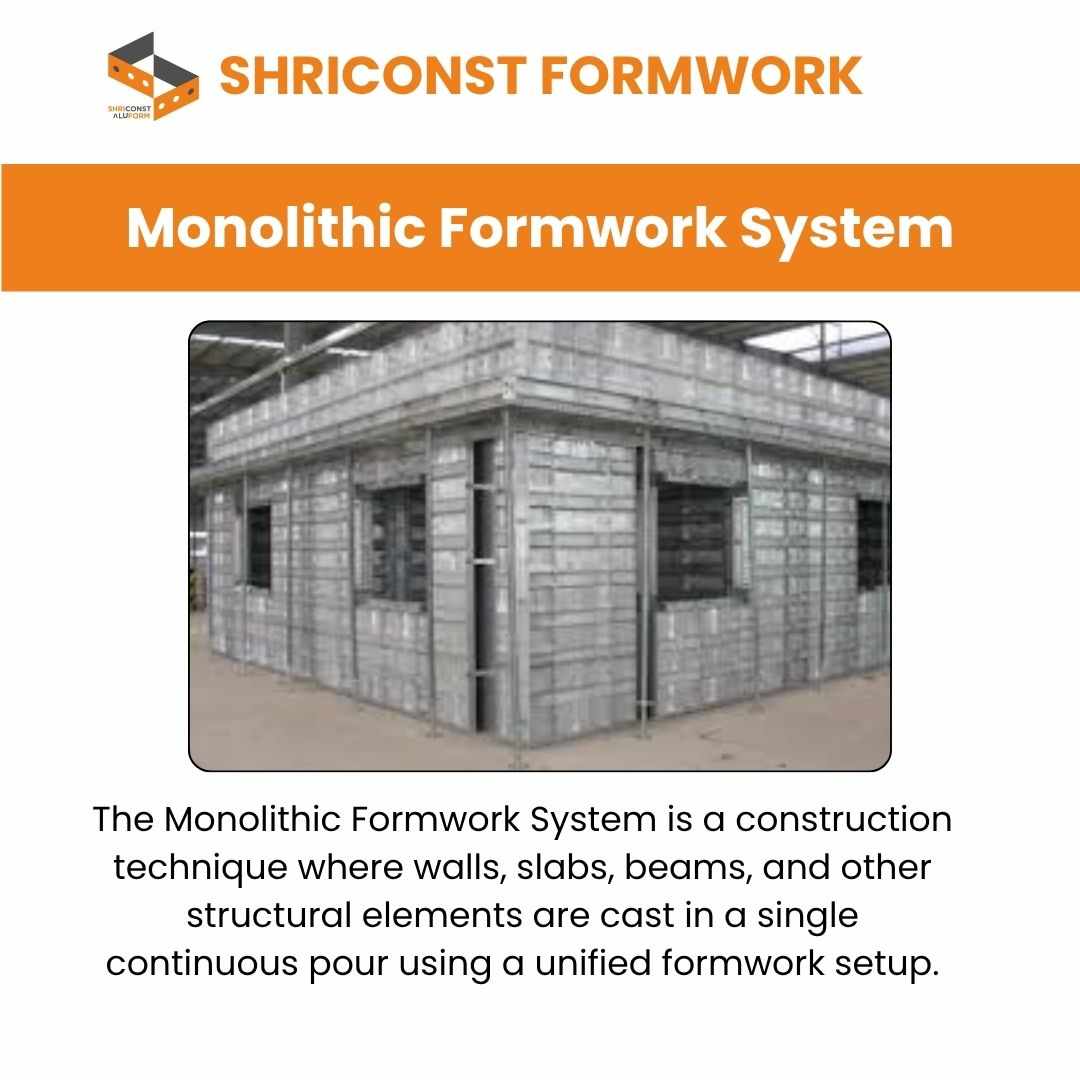

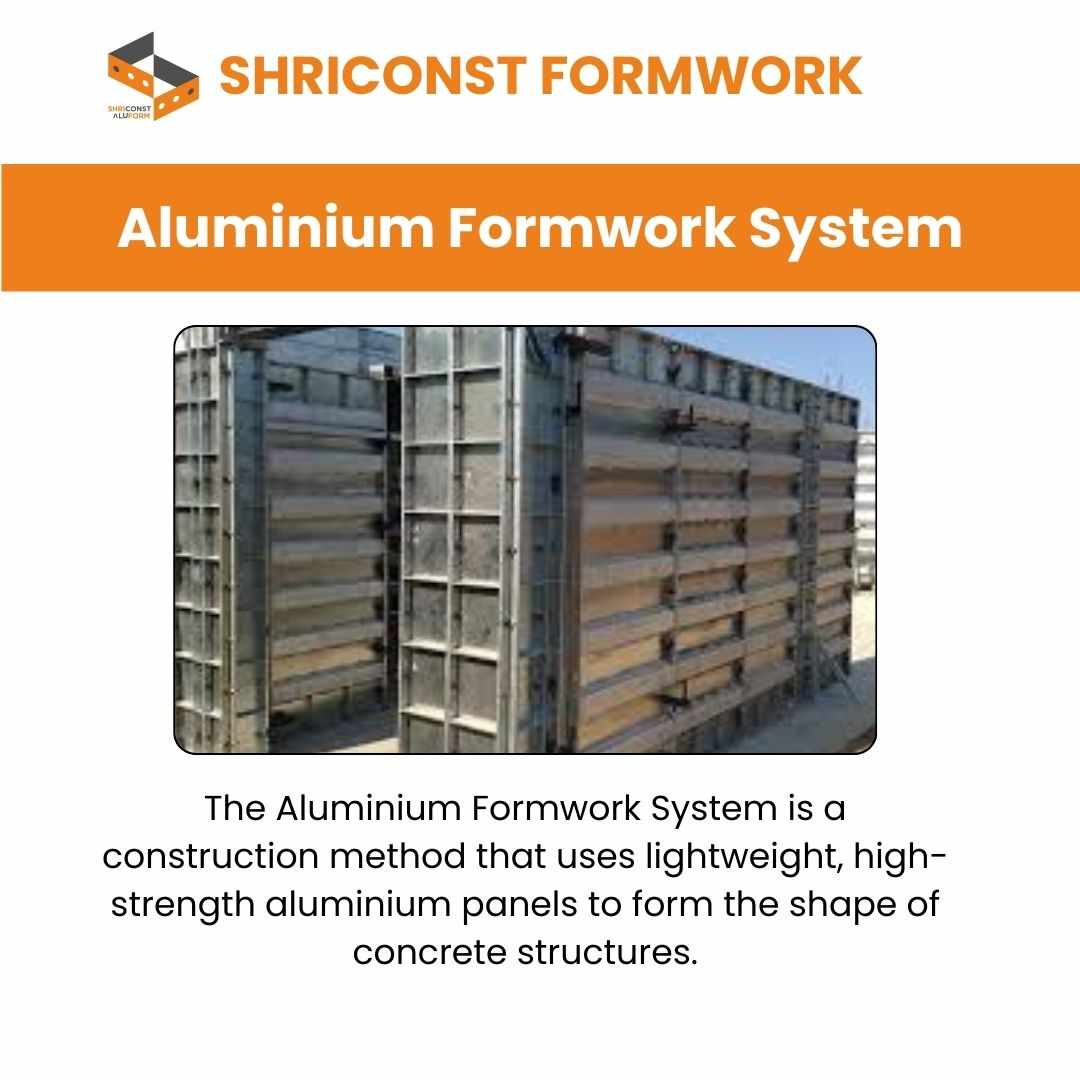

Aluminium formwork is a construction system made from high-strength, lightweight aluminium alloy. It is primarily used for casting concrete structures in place, such as walls, slabs, beams, columns, and staircases. Unlike traditional wooden or steel formwork, aluminium formwork provides an integrated and reusable system that ensures faster construction cycles and superior surface finishes.

The aluminium panels are precisely engineered, ensuring a tight fit and consistent structural integrity. They are easy to assemble, disassemble, and reuse, making them a sustainable choice for high-rise buildings, mass housing projects, and large-scale infrastructure developments.

The Rise of Aluminium Formwork in the Construction Industry

Over the last few decades, the construction industry has shifted its focus toward efficiency and sustainability. Traditional formwork systems, though functional, come with limitations such as high labor costs, longer timelines, and environmental concerns due to timber use. Aluminium formwork addresses all these issues effectively.

Speed and Efficiency – With modular design and easy handling, aluminium formwork accelerates the construction process. Builders can achieve faster floor-to-floor cycle times, making it ideal for large residential or commercial projects.

Durability and Reusability – Aluminium can be reused multiple times without losing its shape or strength, reducing project costs in the long run.

Eco-Friendly Solution – Being recyclable and sustainable, it minimizes waste and eliminates the need for timber, contributing to greener construction practices.

Precision and Quality Finish – The system ensures dimensional accuracy, resulting in uniform wall thickness, perfect alignment, and a superior concrete finish.

Key Components of Aluminium Formwork

An aluminium formwork system typically includes several components that work together to create a robust mould for casting concrete structures. These include:

Wall Panels: Vertical panels that form the walls of the structure.

Beam and Deck Panels: Used for slabs and beams, providing strong horizontal support.

Prop Heads and Soffit Lengths: Support horizontal formwork elements and maintain alignment.

Tie Rods and Pins: Keep panels securely connected during concrete pouring.

Corner and Edge Panels: Provide accurate angles and edges for architectural precision.

Each component is manufactured with exact specifications, ensuring ease of installation and dismantling while maintaining consistency across multiple uses.

Advantages of Using Aluminium Formwork

1. High Construction Speed

Aluminium formwork allows faster assembly due to its lightweight design and modular structure. Workers can install large sections quickly, drastically reducing project timelines.

2. Cost-Effectiveness

While the initial investment may seem higher compared to conventional methods, aluminium formwork is reusable up to 250–300 times, offering significant savings across multiple projects.

3. Superior Finish Quality

Concrete surfaces produced using aluminium formwork are smooth and precise, eliminating the need for external plastering or finishing.

4. Consistency and Strength

This formwork ensures consistent dimensions, producing structurally sound and uniform buildings that meet high safety and quality standards.

5. Environmental Sustainability

Aluminium is recyclable, and its use minimizes the depletion of natural resources like timber. It aligns perfectly with sustainable development goals and eco-friendly building practices.

6. Reduced Labor Dependency

Due to its easy assembly and pre-engineered design, aluminium formwork reduces dependence on skilled labor, minimizing human error and increasing productivity.

Applications of Aluminium Formwork

Aluminium formwork is versatile and can be used across a wide range of construction projects. Its adaptability and reusability make it suitable for:

High-Rise Residential Buildings: Ensures faster floor-to-floor cycles and uniform construction.

Commercial Structures: Delivers precision and quality for offices, malls, and complexes.

Infrastructure Projects: Ideal for bridges, tunnels, and transit stations requiring durable mould systems.

Affordable Housing Projects: Enables mass housing development with quick turnaround times and cost efficiency.

Comparing Aluminium Formwork with Traditional Systems

FeatureAluminium FormworkWooden FormworkSteel FormworkWeightLightweightHeavyVery HeavyReusability250–300 times5–10 times50–100 timesSurface FinishSmooth and uniformRequires plasteringModerateAssembly TimeFastSlowModerateEnvironmental ImpactSustainableUses timberHigh carbon footprintCost EfficiencyHigh long-term savingsLow short-term costModerate

This comparison clearly shows why aluminium formwork is becoming the top choice for modern construction needs.

Why Choose Shriconst Aluform

When it comes to reliable and high-quality aluminium formwork solutions, Shriconst Aluform stands out as a trusted industry leader. The company has a strong reputation for manufacturing precision-engineered formwork systems that meet the specific requirements of modern construction.

Expertise and Innovation

Shriconst Aluform combines years of industry experience with advanced technology to deliver customized solutions. Their team ensures every product meets international standards of safety, strength, and sustainability.

Comprehensive Formwork Solutions

From design to installation, Shriconst Aluform provides end-to-end solutions, ensuring seamless integration into construction workflows.

Commitment to Quality

Quality is at the core of every Shriconst Aluform product. The aluminium used undergoes rigorous testing for strength, corrosion resistance, and durability.

Customer-Centric Approach

The company’s focus on customer satisfaction sets it apart. Whether it’s a small residential project or a large infrastructure venture, clients receive personalized guidance and support throughout their journey.

Sustainable and Future-Ready Technology

Shriconst Aluform emphasizes eco-friendly practices, helping the construction sector transition toward more sustainable and energy-efficient methods. Their aluminium formwork system not only reduces waste but also supports long-term sustainability goals.

The Future of Construction with Aluminium Formwork

As urbanization accelerates and the demand for affordable, high-quality housing increases, aluminium formwork is set to play a pivotal role in shaping the future of global construction. With its unmatched efficiency, environmental benefits, and adaptability, it aligns perfectly with the smart city and green building initiatives being adopted worldwide.

Companies like Shriconst Aluform are at the forefront of this transformation, continuously innovating to provide builders with reliable, cost-effective, and sustainable solutions. By adopting aluminium formwork technology, developers can ensure faster project delivery, superior quality, and long-term cost savings—all while contributing to a cleaner, greener planet.

Conclusion

Aluminium formwork has revolutionized the way modern buildings are constructed, offering unparalleled speed, strength, and sustainability. As the construction industry continues to evolve, the demand for efficient and eco-friendly formwork systems will only grow. Shriconst Aluform remains a trusted partner for builders worldwide, driving excellence through innovation and quality. Choosing aluminium formwork is not just a technological upgrade—it’s a step toward a smarter, more sustainable future in construction.

Write a comment ...