In the evolving world of construction technology, vertical shuttering has emerged as a crucial system that ensures precision, strength, and efficiency in building vertical concrete structures such as columns, walls, and piers. This modern method plays a pivotal role in creating stable frameworks for high-rise buildings and infrastructural projects. By utilizing high-quality aluminum or steel materials, vertical shuttering simplifies the process of forming vertical elements with remarkable accuracy. Companies like Shriconst Aluform have perfected this technique, offering innovative solutions that align with international standards of quality and safety.

Understanding Vertical Shuttering

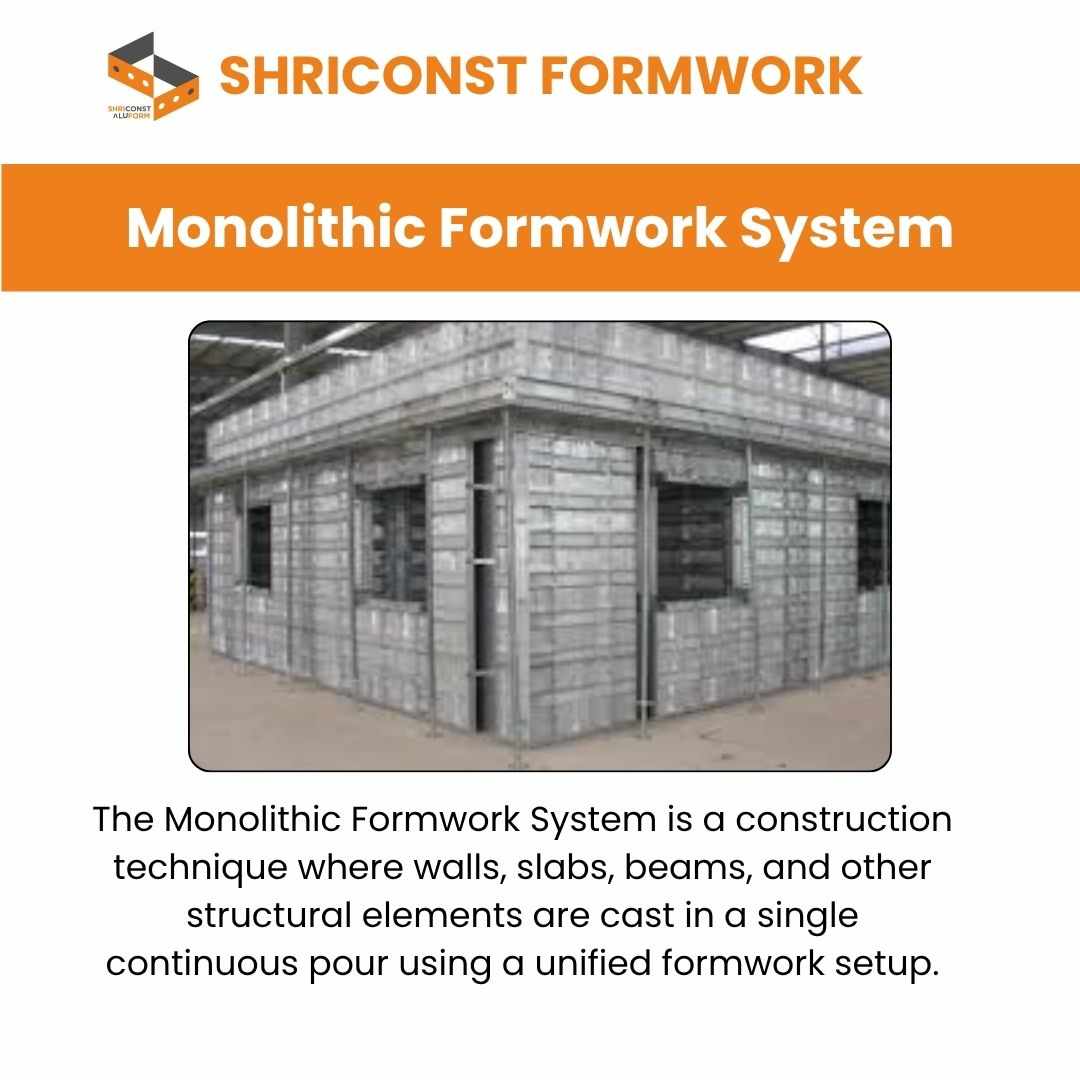

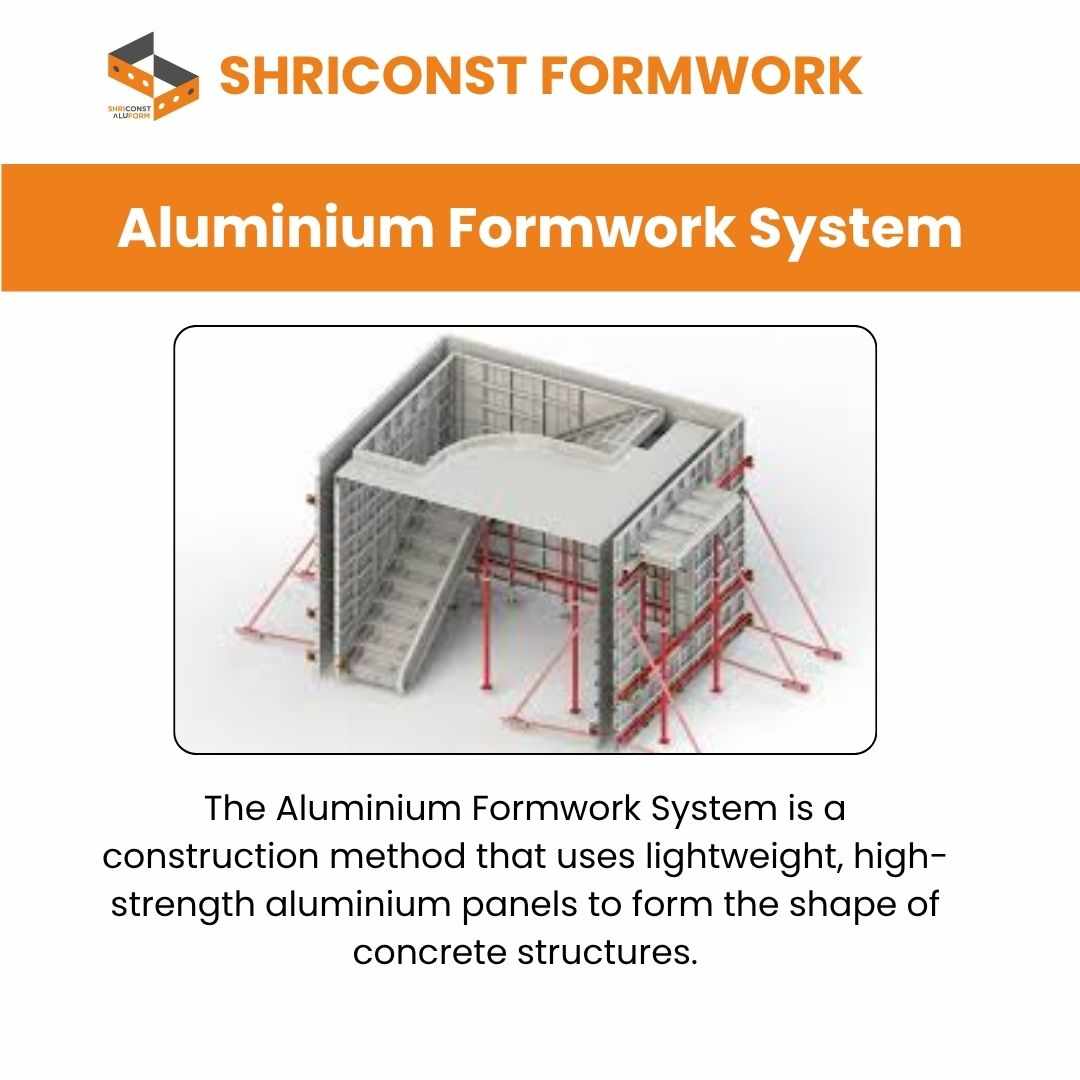

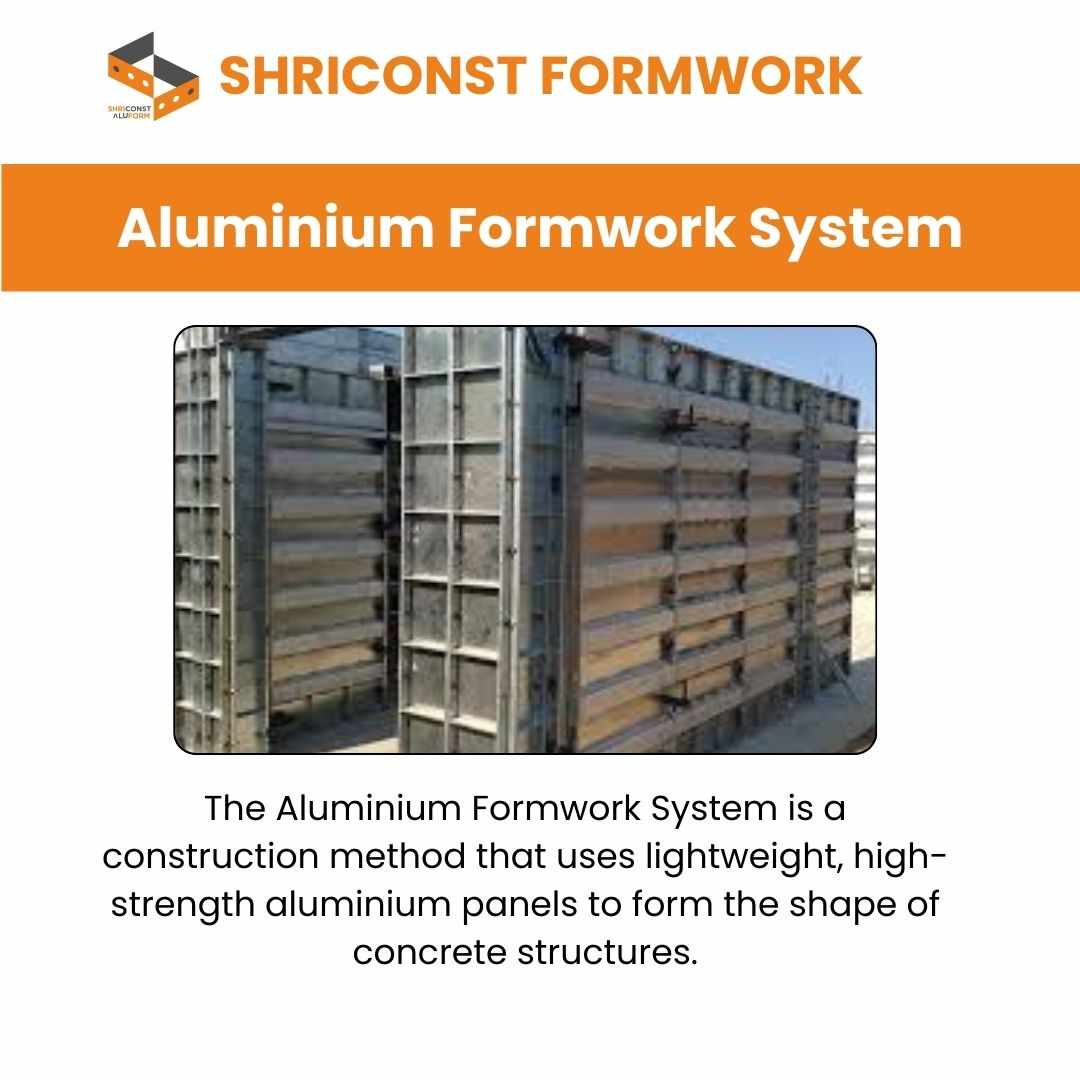

Vertical shuttering refers to a specialized formwork system designed to support vertical structures during the concrete casting process. Unlike traditional wooden formwork, this method employs modular aluminum panels that can be easily assembled and reused multiple times. The system ensures uniformity, quick installation, and smooth finishes for reinforced concrete components. It is especially beneficial for large-scale projects where speed and quality are equally important.

Vertical shuttering systems are primarily used for structural components such as:

Building columns

Shear walls

Bridge piers

Retaining walls

Lift cores

By maintaining consistent vertical alignment and minimizing deformation, vertical shuttering ensures that concrete elements achieve the desired shape, strength, and surface quality.

Components of a Vertical Shuttering System

A typical vertical shuttering system consists of several key components that work in harmony to provide a sturdy and reusable framework:

Formwork Panels: Lightweight aluminum panels that define the shape of the concrete structure.

Tie Rods and Clamps: These hold the panels together securely during concrete pouring.

Walers and Soldiers: Structural members that reinforce the panels, maintaining their alignment.

Corner Angles and Connectors: Used to ensure precision in joint formation.

Safety Platforms: Provide access for workers during assembly and disassembly.

Each component is engineered for maximum durability, ensuring a long service life and minimizing maintenance costs.

Advantages of Vertical Shuttering

Vertical shuttering offers several advantages over conventional methods, making it a preferred choice in today’s fast-paced construction industry:

1. Speed and Efficiency

The modular design allows for quick setup and dismantling. Contractors can reuse the panels multiple times, reducing project timelines and overall costs.

2. Superior Surface Finish

The use of high-quality aluminum panels ensures a smooth and uniform finish, reducing the need for extensive plastering or finishing work.

3. Lightweight and Durable

Aluminum panels are lighter than traditional timber or steel formwork, making handling and transportation easier without compromising strength or stability.

4. Eco-Friendly and Reusable

Vertical shuttering systems are sustainable due to their reusability. They minimize waste and reduce the environmental footprint of construction activities.

5. Cost-Effective in the Long Run

Although the initial investment may be higher than timber formwork, the durability and reusability of the system make it cost-effective over multiple projects.

Application of Vertical Shuttering in Construction

The use of vertical shuttering is widespread across residential, commercial, and infrastructural projects. It is especially advantageous for:

High-rise buildings: Provides consistent and precise vertical alignment across multiple floors.

Bridges and Flyovers: Ensures stability and shape accuracy in piers and supports.

Industrial Facilities: Useful in constructing storage tanks, silos, and concrete towers.

Basement and Retaining Walls: Ideal for below-ground structures that require high-strength vertical walls.

These systems can also be integrated with vertical formwork systems, offering a comprehensive solution for forming both vertical and horizontal concrete components in a synchronized manner.

Steps in the Vertical Shuttering Process

Planning and Design: Engineers design the shuttering layout according to the project’s structural requirements.

Panel Assembly: Formwork panels and accessories are assembled on-site.

Alignment and Reinforcement: The assembled formwork is aligned vertically and reinforced with tie rods and clamps.

Concrete Pouring: Concrete is poured into the shuttered area, ensuring proper compaction and filling.

Curing and Removal: Once the concrete achieves the required strength, the shuttering panels are carefully removed for reuse.

Why Choose Shriconst Aluform for Vertical Shuttering Solutions

Shriconst Aluform stands as a leader in providing innovative and reliable aluminum formwork systems. Their vertical shuttering solutions are designed with precision, emphasizing ease of use, safety, and sustainability. By combining advanced engineering and durable materials, Shriconst Aluform ensures exceptional performance across diverse construction environments.

Key Benefits Offered by Shriconst Aluform:

Customized Solutions: Each project is analyzed to provide tailor-made shuttering designs.

High-Quality Materials: Use of corrosion-resistant aluminum for longevity and reusability.

Expert Support: Professional guidance throughout installation, maintenance, and reuse cycles.

Safety Standards: Compliance with global safety and quality norms to ensure secure work environments.

Innovations in Vertical Shuttering Systems

The construction industry continues to evolve with digital integration, and Shriconst Aluform stays ahead by incorporating modern innovations such as:

3D modeling for design accuracy

Improved locking systems for quick assembly

Enhanced surface coatings for longevity

Compatibility with automated concrete pouring systems

These advancements not only increase efficiency but also improve consistency and reduce human error during the construction process.

The Future of Vertical Shuttering

As urban infrastructure expands, the demand for efficient and sustainable construction solutions continues to rise. Vertical shuttering will play a crucial role in addressing these demands by offering speed, precision, and cost-efficiency. With the integration of modern technologies and materials, the future of shuttering systems promises even greater automation, adaptability, and eco-friendliness.

Conclusion

Vertical shuttering has transformed how modern construction achieves precision and efficiency in building vertical structures. Its reusable nature, lightweight design, and superior finish make it an indispensable tool for today’s builders and engineers. With the expertise of Shriconst Aluform, contractors can confidently adopt these systems to enhance productivity, safety, and quality. As construction technology advances, vertical shuttering will remain a cornerstone of innovative building techniques—ensuring strong, stable, and aesthetically perfect structures for years to come.

Write a comment ...